- OUR PROPRIETARY TECHNOLOGIES

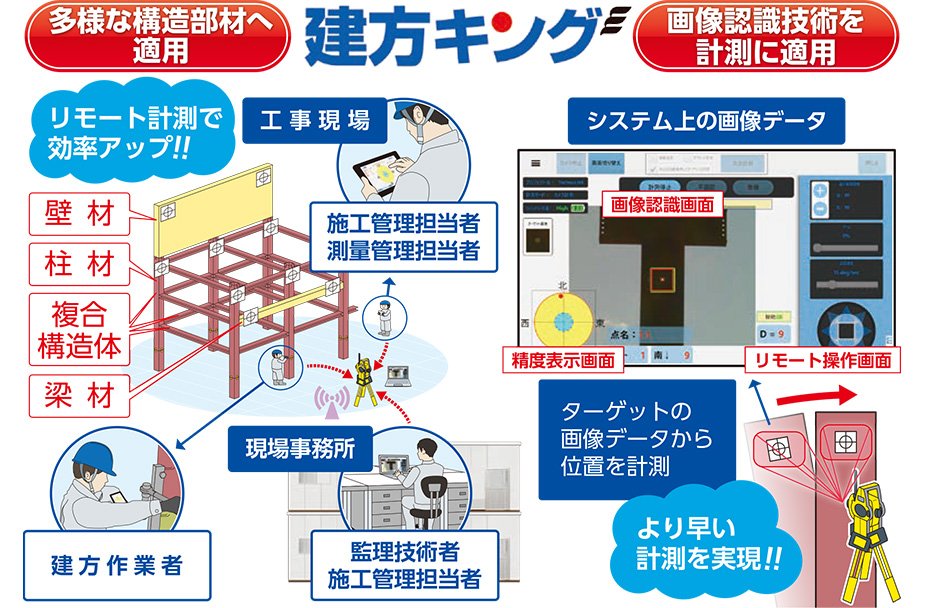

Building Accuracy Control System “TATEKATA KINGE”

Development of TATEKATA KINGE (Evolution)

(Patent Pending)

Digital transformation technology reduces manual labor in the erection process from the measurement to the creation of completion drawings.

TATEKATA KINGE is an evolved and improved version of TATEKATA KING and is the result of the collaboration between TECHNOS CO., LTD. (President Eiji Morita) and Kinsoku Co., Ltd. (President Katsushi Okuno).

TATEKATA KINGE is a system that reduces manual work in a series of construction works by sharing measurement information and performing remote measurement. We have introduced a new image recognition technology to measure the position of the columns, enabling a faster measuring method than the conventional automatic tracking measuring device. Compared with the conventional method using two measurement devices, TATEKATA KINGE reduces approximately 50% of the construction costs and 40% of the construction period due to the reduction in manual labor.

- *ACE UP Method: Construction support method developed by TECHNOS CO., LTD.

-

Figure 1 Overall Image of TATEKATA KINGE

-

1.Development Background

TATEKATA KINGE is a system that has improved the productivity in construction sites with the introduction of DX (Digital Transformation) technology. However, in light of the recent situation at construction sites, we have been working on the development of a new system aimed at further improving productivity at the same time as the development of TATEKATA KING was completed.

The development points targeted by the new system are as follows:

- 1) Labor-saving in measurement tasks

- In the development process of TATEKATA KING, we adopted a method to track the target on the columns manually by a surveyor. The reason for adopting this method was that the cycle of the automatic target tracking method took time for the proper measurement and calculation tasks to be done and did not contribute much to productivity improvement.

- The new system, TATEKATA KINGE, shortens the measurement cycle by developing a technology that combines automatic tracking and image recognition, and at the same time realizes remote measurement for further labor reduction.

- 2) Labor-saving measurement of various structures

- Particularly in measuring buildings with complex designs, multiple targets on beams and walls have to be measured to check the torsional status of the structural members. In addition, multiple targets are also required when measuring a composite structure consisting of multiple columns.

- While the TATEKATA KING system measures multiple targets by repeating single measurements, the new TATEKATA KINGE system aims to easily measure not only beams, walls, and circular structural members but also a composite structure consisting of multiple columns.

-

2.System Overview

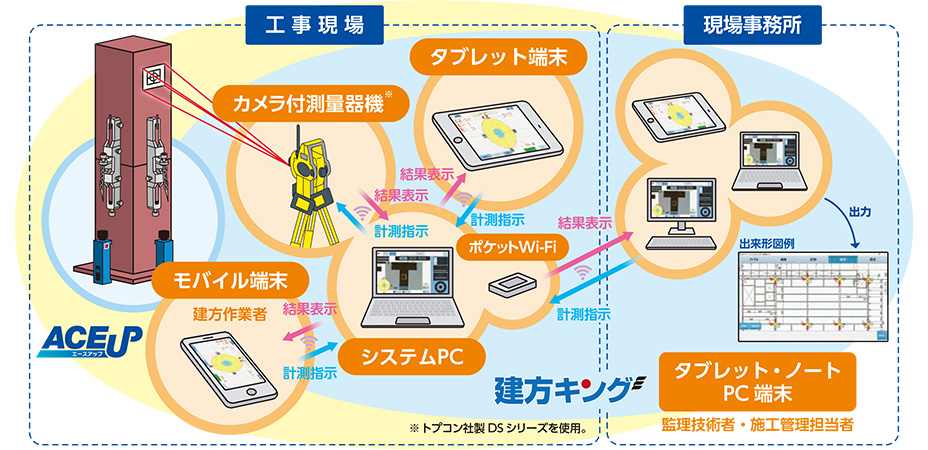

TATEKATA KINGE integrates an automatic tracking measurement device that includes a camera and a PC system installed near the measurement device. Since the PC system can be operated remotely by using a PC, tablet, or mobile phone, it is not necessary for the device operator to be next to the device once it is properly installed.

Measurement management by construction workers and managers is also possible. The supervising engineer or construction manager can take measurements directly from the construction office, or give instructions to the construction workers for corrective or definitive decisions.

Figure 2: System Configuration Diagram

-

3.System Measurement Process

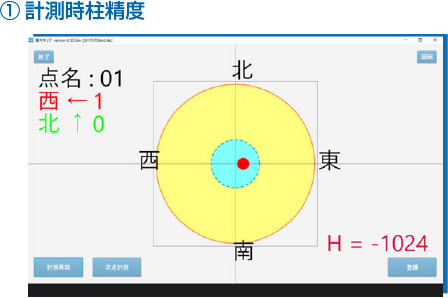

The first measurement focuses on the target with the automatic tracking function. The display of the measurement is the same as the display function of TATEKATA KING. Based on the measurement result, the erection operator starts the adjustment work, during which the measurement devices focus first on the design position of the aimed structure, and the measurement device is fixed on the position.

In the second measurement after the erection adjustment, the camera in the measurement device takes photos of the target area, and the deviation from the design position is calculated.

After the third measurement, the position information is acquired based on the data and the information obtained by the photos, and this operation is repeated until the desired erection adjustment is achieved.

By fixing the measuring device to the design position after the first measurement and developing a method to acquire the position information from the imaging data for the subsequent measurement, the cycle time of the measurement work is shortened.

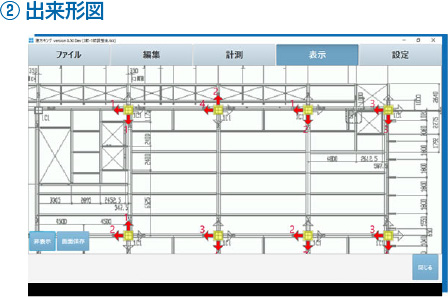

The measurement method is the same for beams, walls, circular structures, and composite structures. By continuously measuring multiple targets, and storing their position information, and then displaying it on the screen, the target to be adjusted can be confirmed and determined.

Figure 3: Image taken near the target

Figure 4: Example of display screen for erection worker

Figure 5: Example of display screen for construction supervisor (same screen for both on-site and office)

-

4.Advantages/Benefits of TATEKATA KINGE

- 1) Improvement in productivity of erection work

- In the conventional measurement method, two device operators and two devices are needed. The two operators send position/location information to the erection worker by radio, and the erection worker himself makes the necessary adjustments. By using TATEKATA KINGE, it is possible to share position/location information between the device operator and the construction worker, and as a consequence the necessary labor force is reduced.

- Moreover, since TATEKATA KINGE allows one to measure remotely, it is not necessary for the survey manager to be constantly next to device and the erection worker themselves, and the construction supervisor also can make the necessary measurements by themselves. As a result, by using TATEKATA KINGE, it is possible to shorten the process by 40% and to reduce costs by 50% compared to the conventional erection method. TATEKATA KINGE has achieved a cost reduction of more than 30% in comparison with its predecessor TATEKATA KING.

- 2) Assurance of reliable construction accuracy

- Due to the fact that the erection worker can make the necessary adjustment while checking the monitor, accuracy can be easily and surely achieved.

- 3) Labor reduction in the measurement task of various structural members

- In addition to columns, the new system makes it possible to measure different composite structures that integrate beams, walls, circular structural members, and columns. For instance, it has succeeded in reducing labor in time-consuming measurement tasks such as the measurement of walls that require multiple measuring points and the measurement of multiple columns after the beams have been inserted, which requires continuous measurements. Furthermore, structures with complex designs that were extremely difficult to measure their coordinate points using conventional methods can be measured instantly, making it possible to easily perform three-dimensional management of connection points of structural members.

- 4) Productivity improvement of supervising engineers and construction management personnel

- The measurement data is visualized and shared not only with erection workers and surveyors, but also with supervising engineers and construction managers simultaneously. Therefore, it is possible to check the construction accuracy not only from the site but also from the office. Since multiple measurement points can be displayed on the device screen, the movement and displacement of the entire building can be captured in real time. As a result, decisions on the amount of adjustment when considering the next step of erection work can be rapidly made.

- 5) Labor reduction in quality inspections

- Once the construction work is completed, the result can be put out as an accomplishment report. Also, necessary inspections can be conducted by supervisors at the office by using the remote system.

As described above, TATEKATA KINGE contributes to the improvement of productivity not only for construction workers and surveyors but also for all the persons involved in the construction process, including construction managers, engineers, and supervisors. In addition, this system contributes to ensuring compliance, such as prevention of data tampering by sharing data.

-

5.Further Development

In addition to providing measurement services using this system TATEKATA KINGE on a contract basis, we will also be expanding our leasing business of the system. In addition, we will add functions to the system to further improve productivity and upgrade the product.