- BUSINESS: What We Do

Foundation Business

When it comes to the CSM Method, TECHNOS is the company to call

TECHNOS and BAUER Maschinen GmbH of Germany have jointly developed the Quattro-cutter and Tandem-cutter to create the CSM (Cutter Soil Mixing) Method for underground continuous wall foundation. While there are only four of these machines in Japan, TECHNOS has three of them.

With our high-quality engineering and construction capabilities backed by many years of experience, we carry out a variety of foundation work with the CSM Method as our mainstay.

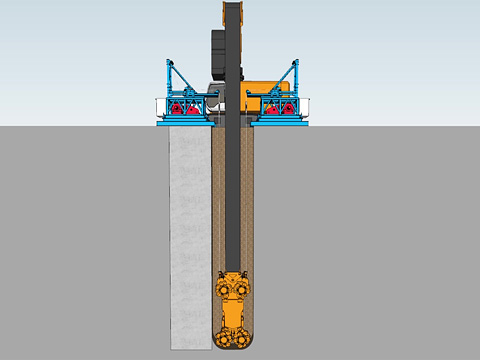

CSM Machine (Quattro Cutter)

CSM Machine (Tandem Cutter)

Underground Continuous Wall Foundation

Soil-Cement Underground Continuous Wall Method (CSM Method)

This is a method of building core pillars such as H-shaped steel or an NS-BOX diaphragm for steel underground continuous walls, in which underground soil and cement milk are stirred and mixed together to create soil-cement walls.

TECHNOS is capable of handling a wide variety of construction methods.

CSM Method

Compared to the conventional method, the CSM Method uses a more compact machine, making it easier to use even in a narrow work environment. As Quattro-cutters and Tandem-cutters are about 1/5 of the height of conventional machines, it provides high stability and reduces any sense of claustrophobia to the surrounding area.

TECHNOS was one of the first companies to introduce the CSM Method to Japan and has achieved greater depth and greater wall thickness in the Soil-Cement Underground Continuous Wall Method. In addition, we have developed the "Excavation Accuracy Measurement System for the CSM Method," which enables us to construct continuous underground walls with higher accuracy than before.

Excavation Accuracy Measurement System for the CSM Method (PR video)

Other methods

- SMW Method

- ECW Method

- TRD Method

- Soil-Cement with Steel-box Underground Continuous Wall Method

Stabilizing Slurry Excavation (SSE) Method

The SSE Method involves excavating the ground using a stabilizing slurry to hold the excavation surface to build core pillars such as reinforced steel bars, H-shaped steel, or NS-BOX diaphragms. Compared to the Soil-Cement Method, this method is capable of constructing an underground continuous wall with greater depth, greater wall thickness, and higher rigidity.

List of Construction Methods

- RC Underground Continuous Wall Method

- Steel Underground Continuous Wall Method (NS-BOX)

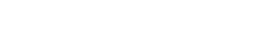

- CRM Method (Excavated Soil Reuse Method)

- K-soil Method (Stabilizing Slurry Solidification Method)

Pile Construction

Pile construction is a method of building reinforced concrete piles on site or erecting ready-made piles (PC piles, PHC piles, steel pipe piles, etc.). TECHNOS is capable of various pile works, but we have the technology called the SENTAN Pile Method, which can check the tip-bearing capacity and control the residual settlement amount.

List of Pile Construction Methods:

- SENTAN Pile Method

- All Casing Method

- Earth Drill Method

- Reverse Method (TBH Method)

- BH Method

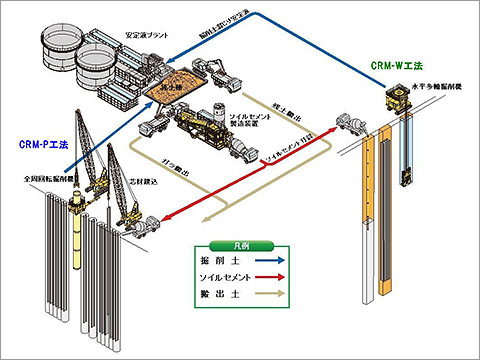

Press-fit Caisson Construction (High Grid Press-fit Caisson Method)

In this method, the press-fit reaction force is applied to the anchor driven into the ground, and transmitted to the hydraulic jack via the rod, and the caisson is sunk and set by overcoming the blade tip resistance and peripheral friction force. The total loading force of several hydraulic jacks installed on the top of the caisson ranges from several hundred to several thousand tons.

There are two types of caissons: the reinforced concrete type and the steel segment (NS shaft) type.

Underground Obstacle Removal

Removal of underground obstacles by the BG excavator is possible to backfill after the obstacles are completely removed. Therefore, there is less disturbance to the surrounding ground and subsequent construction, and it is effective for removing obstacles near the boundary.

List of Methods

- Large-diameter Bedrock Drilling Method (BG method)

- Full-slewing All Casing Method

Earth-Retaining Work (Steel Sheet Pile Press-fitting Method, Silent Piler)

Compared to other methods, the Press-Fitting Method has the advantages of lower vibration and noise in the surrounding environment, no disturbance to the ground, and no sludge generation.