- BUSINESS: What We Do

Renovation Business

Contributing to Society through Proprietary Technologies for Major Infrastructure Renovation

Elevated bridges and bridges built for highways and the like during the rapid economic growth period (1955-1973) in Japan are entering a period of major renovation. Compared to new construction works, these renewal works for such structures as expressways are often carried out while it is in use. Therefore, it requires more construction expertise and techniques.

We at TECHNOS possess many proprietary technologies for this renewal work and have been contributing to society by providing seismic reinforcement works as well as repair and maintenance works for structures like bridges and tunnels.

Seismic Reinforcement Works for Elevated Highway Bridges

Many elevated bridges such as highways have been constructed more than 50 years ago and require seismic reinforcement and measures to prevent concrete pieces from peeling off.

We undertake seismic reinforcement works, concrete peeling prevention measures, and repair works as a prime contractor, and sometimes as a subcontractor.

- Seismic Reinforcement Work

- Concrete Peeling Prevention Measures

- Repair Work

Renovation Works for Power Facilities

Many power facilities have been in use for a long time since constructed and require tunnel repairs, channel repairs, etc.

We undertake tunnel reinforcement, waterway repair, and dam apron repair works as a prime contractor, and sometimes as a subcontractor.

- Tunnel Repair Work

- Waterway Repair Work

- Dam Apron Scouring and Repair Work

Civil Engineering Renovation Works

We carry out various civil engineering renovation works such as renovations of athletic fields and streets for local governments.

We undertake renovation works as a prime contractor, and also we can carry out other public works as a subcontractor.

TECHNOS’ Technologies

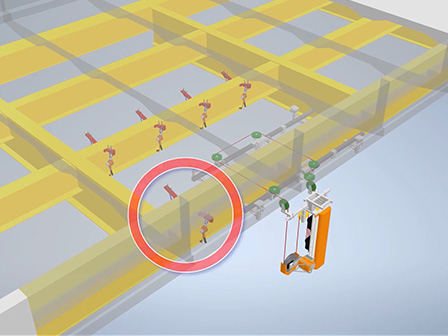

KIRIKATA JOHZU (Bridge floor slab cutting method aims to shorten road closure periods)

“KIRIKATA JOHZU” is a floor slab cutting method which all cutting equipment are placed on the underside of the floor slab. Compared to the conventional method, this method reduces the floor slab replacement time by 50% and contributes to shorter road closure period during construction. It efficiently separates the floor slab from the main girder of the bridge by using a dry high-precision wire saw.

In the conventional method, a large tensile force is applied to the main girder during stripping, and has a risk of being severely deformed. With KIRIKATA JOHZU method, however, there is no such concern or risk of damage to the existing structure.

*This method is jointly developed by Seiwa Dia Corporation and TECHNOS CO., LTD.

Seismic Wrap Method

This is an earthquake-resistant reinforcement method. Steel plates cut into corrugations are piled up around existing concrete columns, and the gaps between the concrete columns and the corrugated plates are filled with mortar to prevent shear failure and improve the toughness of the columns.

Polymer Cement Mortar (PCM) Spraying Method

This PCM spraying method improves seismic performance by spraying polymer cement mortar to integrate it with the existing structure, such as concrete, steel, etc.

The construction period can be shortened because a wide area can be constructed at once.

Water Jet Method

This method utilizes a mechanism that destroys an object by the collision pressure of a high-speed water jet sprayed from a nozzle. Unlike breakers, rock drills, and other types of mechanisms that can damage the object, this method does not damage the surrounding concrete or rebars.