- OUR PROPRIETARY TECHNOLOGIES

Bridge Floor Slab Cutting Method “KIRIKATA JOHZU”

Development of Bridge Floor Slab Cutting Method “KIRIKATA JOHZU”

Floor Slab Cutting Method to Shorten Road Closure Periods

TECHNOS CO., LTD. has jointly developed a bridge slab cutting method called "Kirikata Johzu” with Seiwa Dia Corporation (Location: Setagaya-ku, Tokyo).

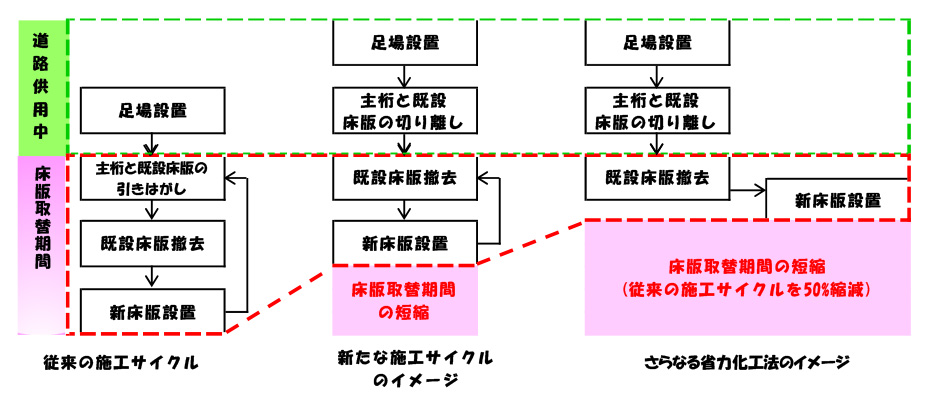

“Kirikata Johzu” is a method of separating the floor slab from the main girder while the road remains in service. It is a completely different approach from the conventional hydraulic separating method, in which the floor slab is detached after the road is closed, and it reduces the time for floor slab replacement by 50%, contributing to the reduction of road closure periods.

-

1.Background

Many bridges in Japan such as those for expressways are more than 50 years old, and the replacement work for their aging floor slabs is in progress. In this type of bridge replacement work, rapid construction is required to shorten road closure periods as much as possible in order to reduce the impact on drivers.

Several rapid installation methods using precast concrete slabs have been developed, whereas there are few methods for the rapid dismantling of floor slabs. That is why we have developed "Kirikata Johzu” as a solution to this problem.

-

2.Outline

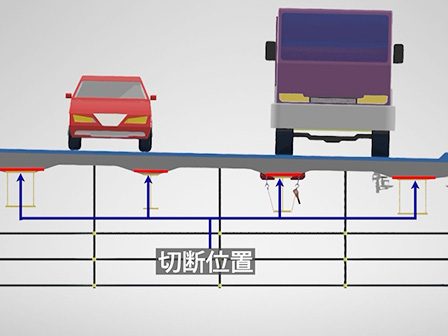

Kirikata Johzu, the dry-type, high-precision wire saw, efficiently separates the floor slabs from the main girders of bridges.

Its features are as follows:

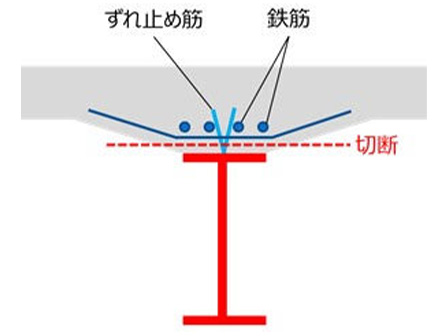

- 1) Cutting the main girder and slab at the bottom of the floor slab

- The cutting work is performed only with the equipment installed under the floor slab, without placing any equipment on it.

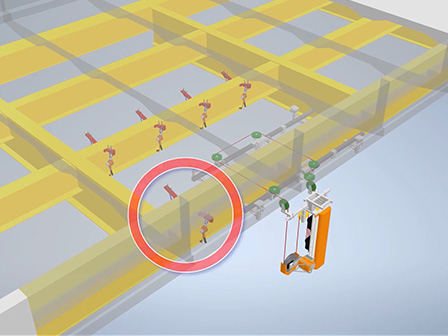

Figure 1: Cutting test using full-scale model

Figure 2: Installation of cutting equipment and cutting locations

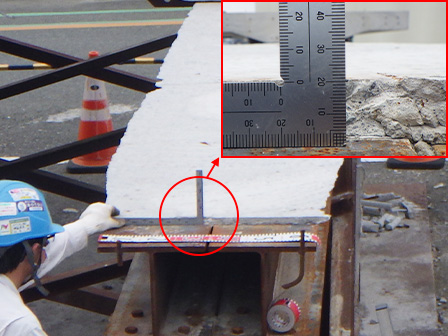

- 2) Cutting Performance with excellent flatness

-

We have developed a new cutting method that is unaffected by the presence of rebar or steel in the concrete. It is possible to cut with a high precision of ±8mm, and the cutting area can be minimized without affecting the main girder. The removal of concrete debris left on the girder after stopping traffic is also significantly reduced.

Figure 3: Cutting of the floor slab

Figure 4: Concrete section on the girder

Figure 5: Removal of concrete debris on the girder

- 3) Reduced impact on the surrounding environment

- Compared with the conventional method, the cutting noise is reduced, and the use of a dry, high-precision wire saw eliminates the generation of muddy water, thereby reducing the impact on the surrounding environment.

- 4) Reduction of floor slab replacement period and construction road closure periods

-

The floor slab is cut from the main girder while the road is in service. A newly developed special fixing jig is installed at the planned and completed cutting locations to ensure the same structural safety after cutting.

As a result, the process of removing the floor slabs after the bridge is closed to traffic can reduce labor, and the time required to replace the floor slabs can be reduced by 50%. The time required to close the bridge to traffic can also be shortened by about 18% (based on the trial calculation using a bridge length of 300 meters).

Figure 6: Installation of fixing jig

(planned and completed cutting locations)

Figure 7: Details of special fixing jig installation

- 5) Safer floor slab removal work

-

In the conventional hydraulic tearing off method, workers enter the lower part of the floor slab while the floor slab is hydraulically torn off, and gas cuts the bar to prevent displacement between the main girder and the floor slab. On the other hand, since the floor slabs are cut in advance in the "Kirikata Johzu" method, such dangerous work does not occur, and the floor slabs can be removed in a safe environment.

Figure 8: Cut section

- 6) Removal work without damaging the main girder

-

In the conventional hydraulic method, a large tensile force is applied to the main girder during stripping. In particular, box girders and heavily corroded main girders are at risk of being severely deformed. In the case of the "Kirikata Johzu” method, in which the main girder and floor slab are separated beforehand, there is neither such concern nor risk of damage to the existing structure.

-

3.Future plans

We will proceed with a full-scale deployment of this technology for on-site construction. In addition to labor reduction in the repetitive construction process of removal and installation during road closure periods, we aim to develop a further labor-saving method that separates removal and installation.

Figure 9: Floor slab replacement procedure

We have developed “Kirikata Johzu” exclusively for non-composite girder bridges. In the future, we would like to study the possibility of applying this technology to composite girder bridges as well.