- OUR PROPRIETARY TECHNOLOGIES

Building Accuracy Control System "TATEKATA KING"

Development of Building Accuracy Control System “TATEKATA KING”

Achieve further productivity improvement of building construction with IoT Technology and contribute to the working style reform!

TATEKATA KING is the result of the collaboration between TECHNOS CO., LTD., Kinsoku Co., Ltd. (Location: Kyoto-city, Kyoto) , and Kinki University (Faculty of Sciences and Technology, Department of Information).

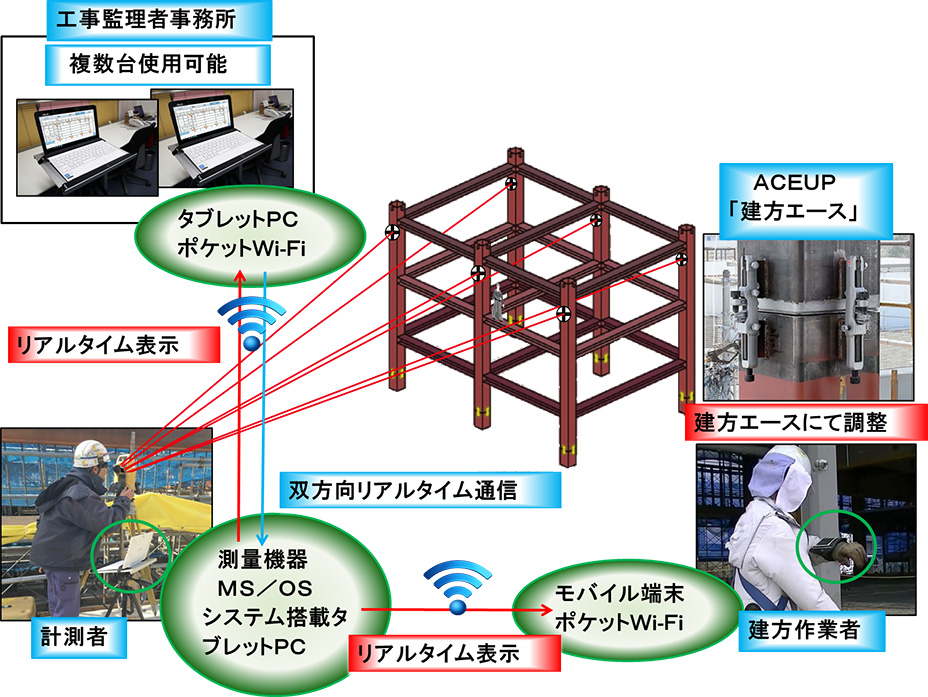

This system allows the visualization of the construction measurements and construction accuracy during the erection period such as the assembling of steel frames. In addition, the TATEKATA KING System allows multiple people to check the result of measurement in real time simultaneously on their mobile devices. By using TATEKATA KING, it is possible to efficiently and quickly control the accuracy of the construction structure compared to the conventional method, and at the same time, it is possible to reduce the necessary workforce in the construction site.

- *1."TATEKATA KING" is a system that supports the "ACEUP" construction method, which is a wireless construction method sold by TECHNOS CO., LTD. ("ACEUP" is a registered trademark of TECHNOS CO., LTD.)

- *2."TATEKATA KING" is a NETIS registered product. (Registration number "KK-180058-A")

-

1.Development Background

These days, in the construction industry, labor shortages due to aging skilled engineers and architects and the decrease in the number of construction workers have become urgent issues. Even for measurements, which are indispensable for construction sites, there are many tasks that require refined skills and abundant experience, and it takes a lot of personnel and time at the construction site. In addition, in the supervision work, it is difficult to give instructions in real time with conventional measurement methods, and it takes a lot of time because instructions are given after confirming the measurement results.

For these reasons, we have developed this system to improve these issues and improve productivity in construction works. (Figure 1)

Figure 1: Image (Real time visualization of the shared data)

-

2.System Overview

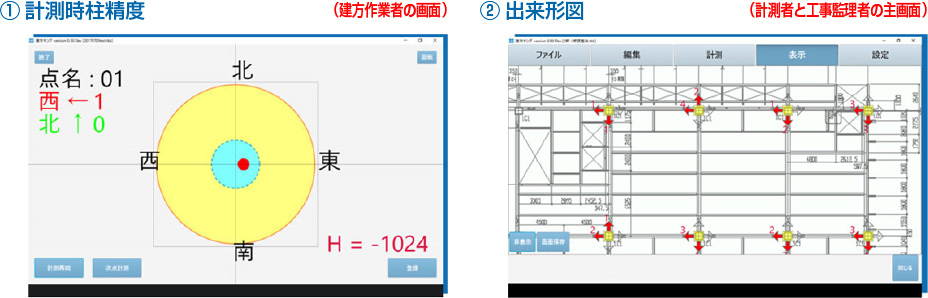

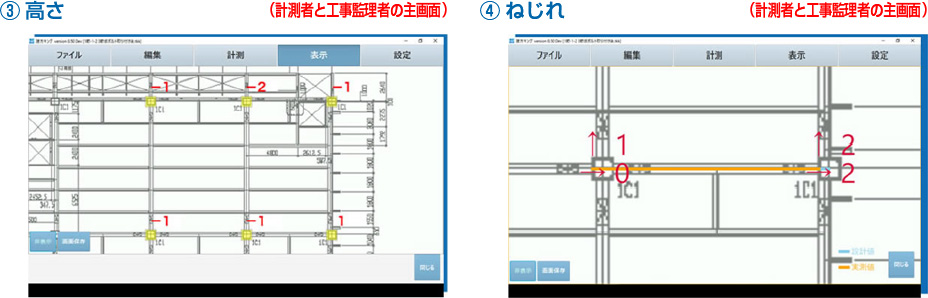

This system uses Wi-Fi (wireless LAN) to display the accurate information in real time on the mobile device used by the construction worker. On the mobile device, the position information (horizontal and vertical) of the steel frame is displayed in figures and numerical values using the function developed independently (Figure 2).

Moreover, in the conventional measurement method, two devices are needed to transmit the position information of the steel frame to the construction worker by radio; however, with the TATEKATA KING System, measurements can be performed by one person and just one measuring device, so the need for radio communication is eliminated.

The measured information can be shared not only by the measurer and the construction worker, but also by the construction supervisor at the same time. Therefore, it is possible to construct the high-precision erection with no time lag.

Figure 2: Easy-to-understand display of measurement differences with charts and numbers①

Figure 2: Easy-to-understand display of measurement differences with charts and numbers②

-

3.Advantages of TATEKATA KING

- ①Easy and reliable construction accuracy

- The measurement data is displayed on the monitor in real time. The operator can adjust the construction position while checking the monitor and as a consequence, the construction accuracy can be secured more easily and reliably than before.

- ②Reduction of labor force and improvement of construction supervision

- The visualized information can be shared not only by the measurer and the construction worker, but also by the construction supervisor. Therefore, the construction supervisor can check the accuracy in real time while anywhere at any time.

- ③Improvement of productivity

- With the conventional method, two devices and two operators are needed; however, just one device and one operator are needed with the TATEKATA KING System, and in addition, radio communication is eliminated, so as a result, work efficiency is significantly improved.

- *The conventional method takes around 40 minutes to adjust the erection of eight columns. The same job can be done in just 16 minutes by using the TATEKATA KING System, an approximate time reduction of 40%.

- ④Cost reduction

- Since just one operator is required, it is expected that the cost can be reduced by about 30%.

-

4.Further Development

We actively engage in the leasing business of TATEKATA KING as well as provide measuring services on a contractual basis. Moreover, we will add additional functions aimed at further productivity improvement to upgrade our products.